Image: Audi AG

Circular economy in automotive engineering.

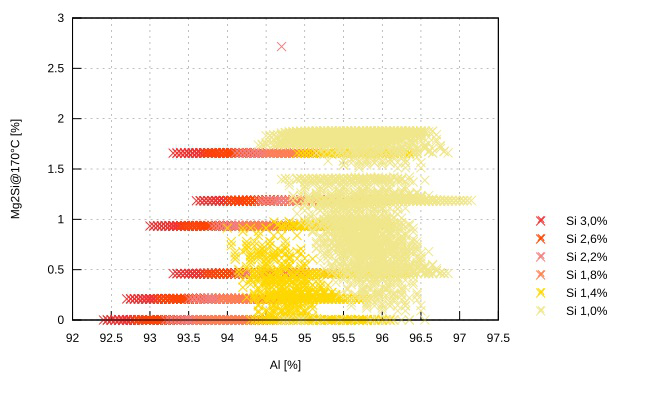

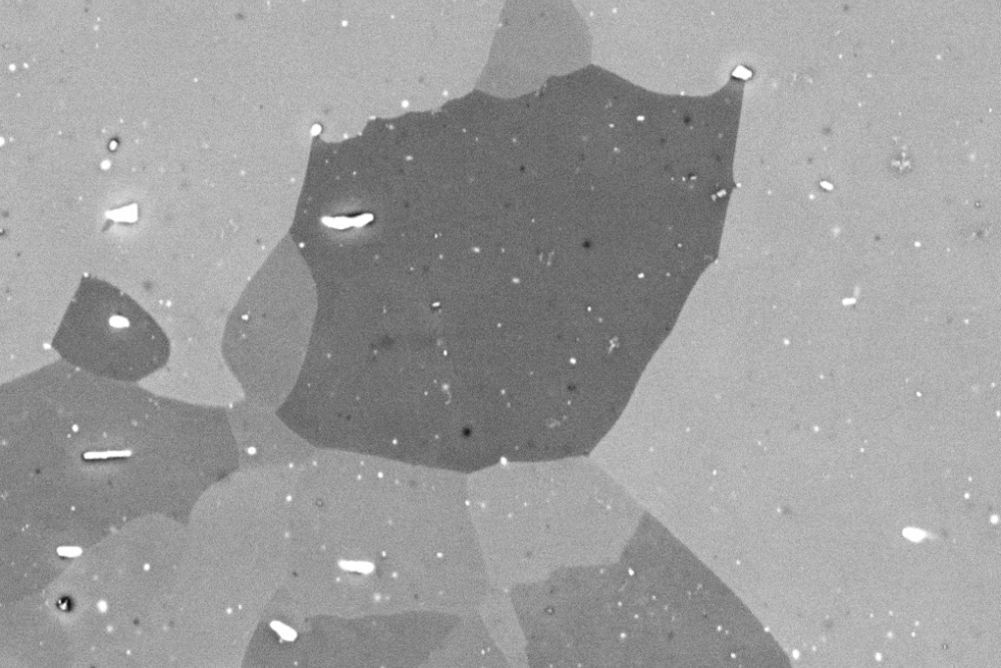

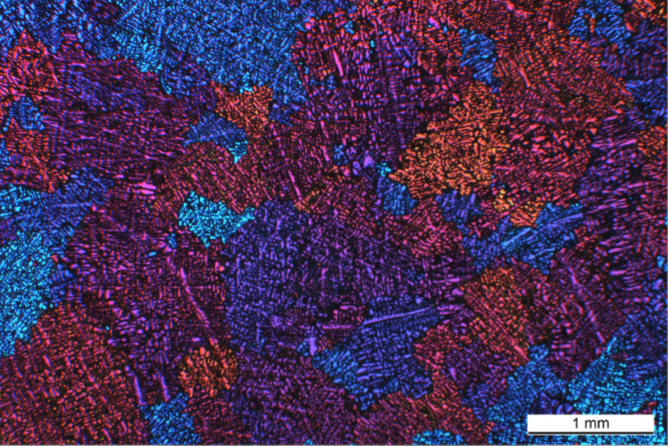

The overarching goal of the joint project is to increase the lightweight construction potential of aluminum alloys for mobility applications while at the same time significantly improving sustainability, climate friendliness and cost efficiency. To increase sustainability and climate friendliness, secondary aluminum should be used from various sources, but in particular from end-of-life (EoL) scrap from vehicles. For this purpose, the entire process chain, starting from the EoL material sorting, the alloy production and composition through the processing to the component, must be considered and adapted and thereby built up across locations and digitally networked. Corresponding increases in efficiency can only be achieved through this holistic view of all steps along the process chain. Furthermore, it should be proven that through targeted adaptation of the entire process chain, the use of EoL material is also possible and cost-effectively mapped for highly stressed aluminum components.