JMatPro in Action

JMatPro Demo

Please feel free to download the demo version of JMatPro. We do not require you to register but any comment or feedback you can make at [email protected] is welcome.

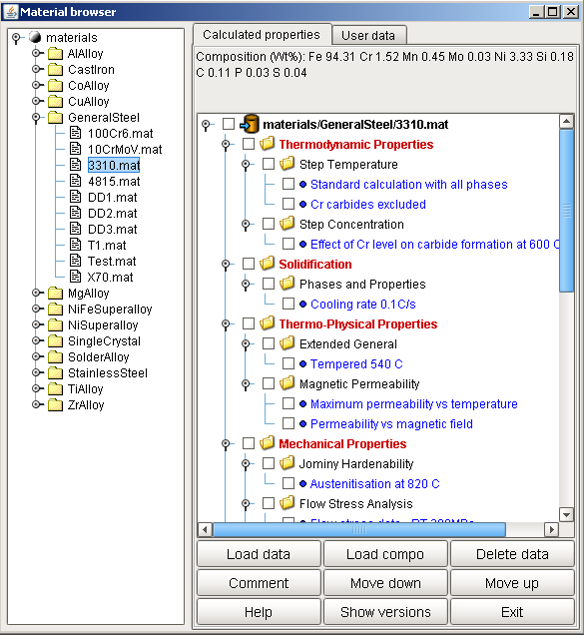

Material Browser

JMatPro calculation results are displayed clearly in a corresponding browser.

In JMatPro, a file has a certain chemical composition. An advantage of JMatPro is that many different compositions can be calculated to a material designation.

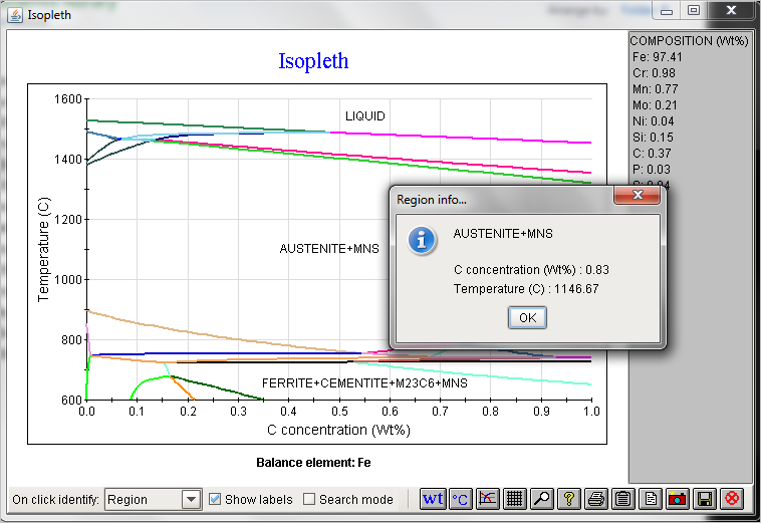

Calculation of Phase Diagrams (Isopleths)

JMatPro calculates arbitrary pseudo-binary slices through the phase space. Such isopleth diagrams correspond optically to the binary phase diagrams, e.g. Iron-carbon phase diagram. However, the calculated diagrams are much more relevant to practice, as also other alloying elements are included.

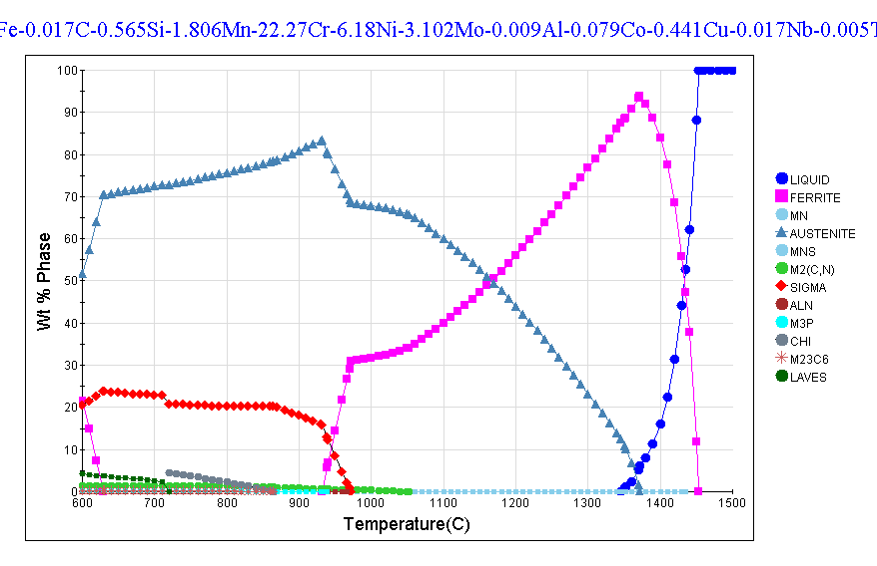

Equilibrium Calculations

The fastest way to calculate the phase contributions, phase composition, and distribution of chemical elements in an alloy is temperature stepping. Here, starting from all known phases, the thermodynamic equilibrium is calculated as a function of the temperature. The example shows a duplex steel which has equal phase proportions of ferrite and austenite at a duplex temperature of about 1160 ° C.

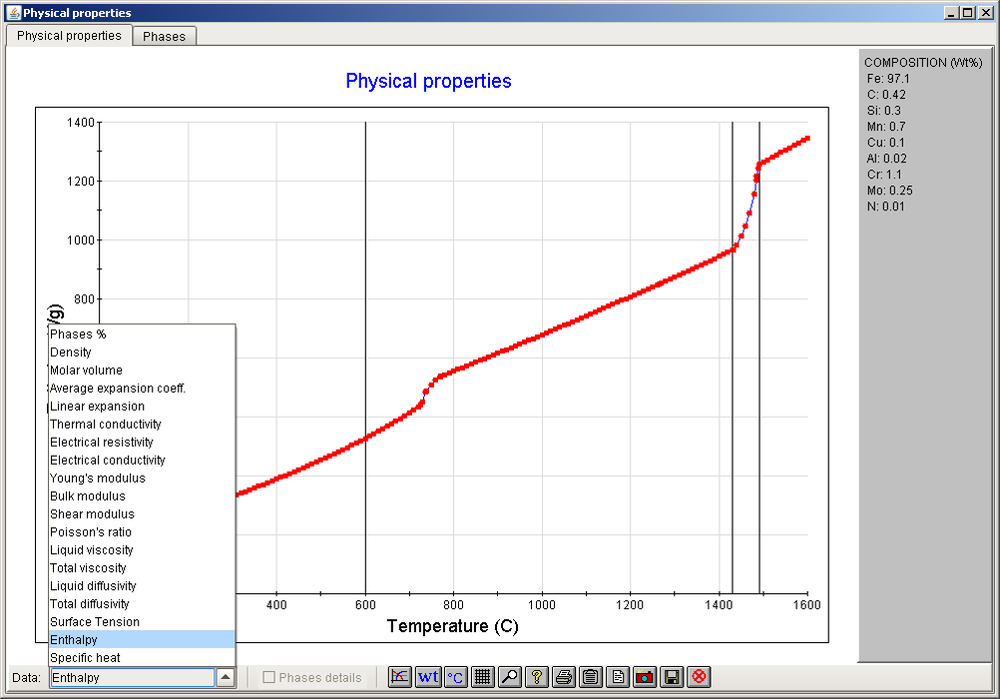

Calculation of thermo-physicalischer Properties

From the calculated phase fractions and their chemical composition, JMatPro calculates a whole range of properties as a function of composition and temperature. This is a basis for creating material maps for FEM calculations. Since all data is derived from a physically based model, it is also consistent and consistent.

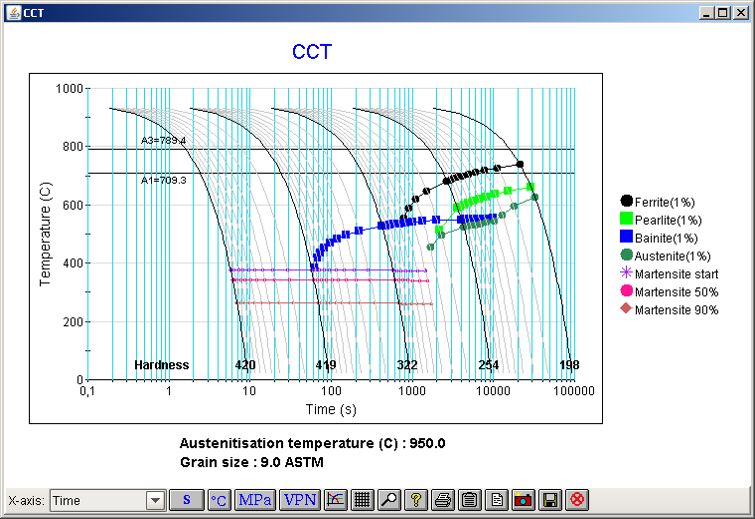

Phase Transformations and TTT-Diagrams

JMatPro calculates not only thermodynamic equilibria but also phase transformations – in the case of steels these are continuous and isothermal time-temperature transformation diagrams (ZTU) as well as time-temperature austenitisation diagrams (ZTA). In this way, JMatPro can also calculate the material properties as a function of the cooling and heating rate.

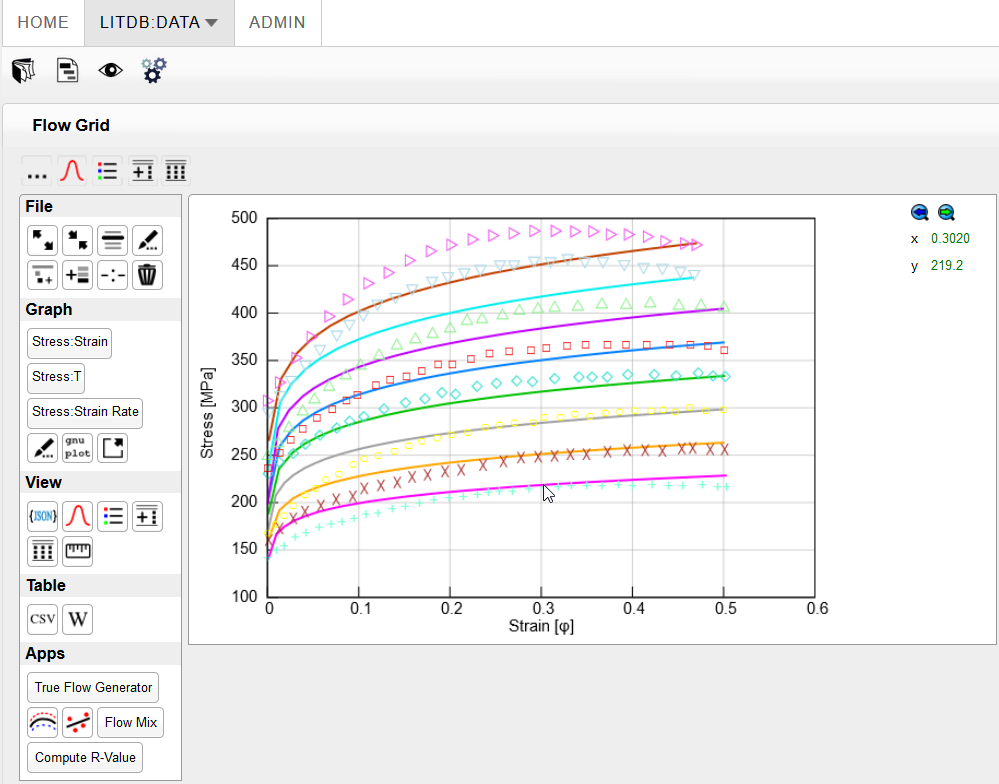

Strength and Flow Curves

For forming simulation and heat treatment simulation, flow curves as a function of temperature and forming speed are required. JMatPro calculates these over wide temperature ranges and speeds.